Project Details

Client: National Grid

Customer: Morrison Utility Services

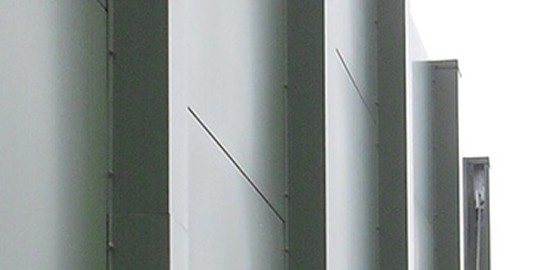

Service: Acoustic Barrier

Project completion: October 2013

The Project

Employed by Morrison Utility Services, Kimpton Energy Solutions were to design, manufacture and install an Acoustic Barrier that would reduce the noise levels of the transformers and associated electrical equipment that generate the electricity at the point where the West of Duddon Sands Offshore Wind Farm reaches land and connects to the National Grid.

An ‘L’ shaped configuration for the barrier was designed and built by Kimpton. The barrier is designed to provide an overall noise level reduction of 12dBA and has an overall measurement of 70m long and 5m high and the modular construction allowed for easy manufacturing, shipping and installation on site.